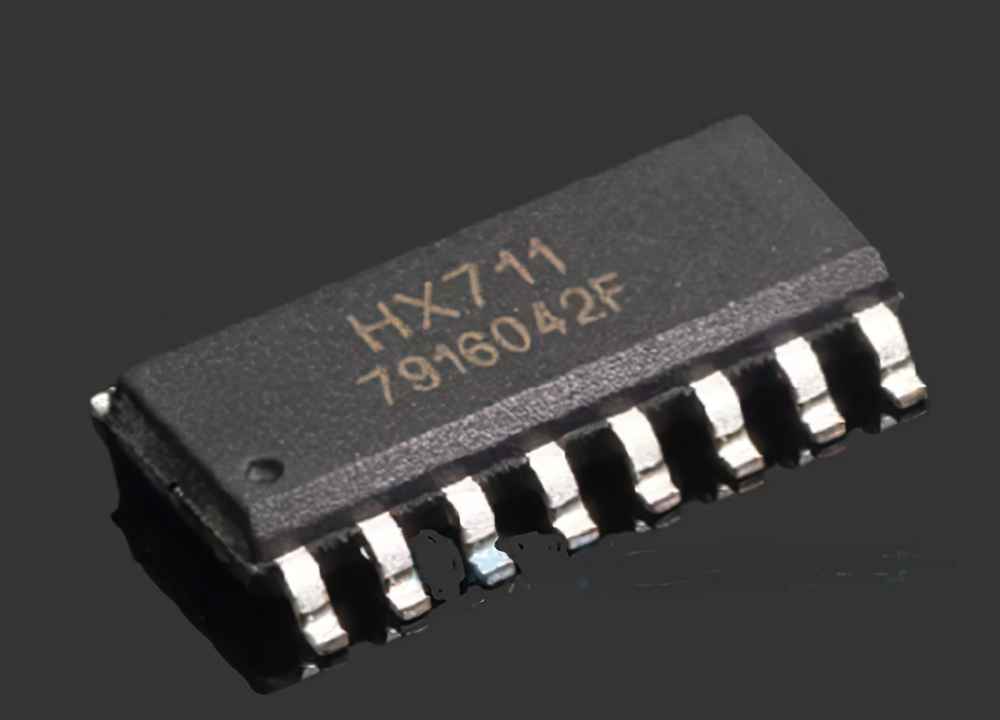

The AVIA HX711 is a popular and widely used 24-bit analog-to-digital converter (ADC) designed to interface with load cells for accurate weight measurement. Whether you're building a digital scale or working on a robotics project, the HX711 is often the go-to choice due to its precision and low cost. However, as with any electronic component, problems can arise that hinder its performance. Understanding these common issues and how to troubleshoot them can save you time and effort. In this guide, we’ll explore frequent problems faced when working with the HX711 and provide solutions to address them.

1. No Output or Unstable Output

One of the most common issues users encounter when working with the HX711 is a complete lack of output or erratic readings from the load cell. This can happen for several reasons, and pinpointing the root cause is essential for fixing the problem.

Possible Causes and Solutions:

Improper Wiring: The first thing to check is the wiring of the HX711. Ensure that the connections are correct, particularly the connections to the load cell. The HX711 typically has four pins for the load cell: A+, A-, B+, and B-. These should be connected properly, with A+ and A- corresponding to the positive and negative terminals of the load cell, respectively. Likewise, B+ and B- should be correctly connected. Double-check these connections to avoid short circuits or disconnected wires.

Power Supply Issues: If the HX711 isn’t receiving a stable power supply, it may fail to provide reliable output. Ensure that the power supply is within the recommended voltage range (typically 2.7V to 5.5V). A fluctuating or insufficient power supply can lead to unstable readings or a lack of output altogether. Consider using a regulated power supply to avoid this issue.

Faulty Load Cell: If the load cell is defective or damaged, the HX711 may not be able to produce valid readings. In this case, swapping out the load cell for a known functional one can help determine if the load cell is the issue. Look for any visible signs of wear, damage, or improper soldering.

2. Reading is Stuck at a Certain Value

Sometimes the HX711 will produce a constant reading that does not change when weight is applied or removed from the load cell. This issue can occur for several reasons, and troubleshooting involves checking both the hardware and software setup.

Possible Causes and Solutions:

Incorrect Calibration: If your system is showing a constant reading, it might be due to incorrect calibration. The HX711 needs to be calibrated properly to provide accurate readings. You will need to adjust the calibration factor to match your load cell’s specifications. Ensure that you are using the correct calibration procedure and that the system is being calibrated with known weights to account for any discrepancies.

Faulty HX711 Module: Occasionally, the HX711 module itself may be faulty. In such cases, the module may need to be replaced. If possible, try using a different HX711 to see if the issue persists.

Software Errors: Incorrect code or configuration may cause the readings to become stuck at a certain value. Review your code and ensure that you have properly initialized the HX711, defined the correct pins, and used the right sampling rates. For Arduino users, libraries like "HX711.h" can simplify initialization and reduce potential errors in your program.

3. Fluctuating or Noisy Readings

Another common issue when working with the HX711 is fluctuating or noisy output, where the values change unexpectedly even when no weight is applied or the load is stable. This can be caused by various factors, including electrical noise or incorrect system configuration.

Possible Causes and Solutions:

Electrical Noise: The HX711 can be susceptible to electromagnetic interference (EMI) and noise, especially in environments with high-powered electrical devices or poor grounding. To mitigate this issue, ensure that the HX711 is well shielded from any potential sources of EMI. Using twisted pair wires for the load cell connections and adding capacitors to the power lines can help reduce noise.

Incorrect Gain Settings: The HX711 supports different gain settings, which can impact the accuracy of the readings. If the gain is set too high, the system may become more sensitive to noise. Try adjusting the gain settings in your code to see if it reduces fluctuations. The HX711 typically offers gain values of 128 and 64, with 128 providing higher sensitivity.

Load Cell Placement: Ensure that the load cell is placed on a stable surface. If the load cell is subjected to vibrations, it may result in fluctuating readings. Properly isolating the load cell from vibrations and environmental disturbances can help stabilize the readings.

4. Inconsistent Calibration

One of the major challenges when working with HX711 is ensuring consistent calibration, especially if the system is moved or reset frequently. If the readings change significantly after the system is powered off or reset, it might indicate a calibration problem.

Possible Causes and Solutions:

Re-calibration after Reset: The HX711 does not retain calibration settings when powered off or reset, so you will need to perform calibration each time you restart your system. Ensure that you have implemented a reliable calibration routine in your software to reset the calibration factors after every reset or power cycle.

Load Cell Drift: Load cells can experience drift over time, leading to gradual changes in readings. If your system is drifting, consider re-calibrating the system periodically or using a load cell with better stability.

Temperature Changes: Significant temperature fluctuations can affect the accuracy of your load cell and HX711. Load cells and amplifiers are sensitive to temperature, so make sure your setup is in an environment with stable temperature conditions.

5. Problems with Signal Integrity

Signal integrity issues can severely affect the performance of the HX711, leading to inaccurate weight measurements. These problems often arise due to long or improper wiring or poor connection quality.

Possible Causes and Solutions:

Long Wiring Distance: Long wires between the HX711 and the load cell can introduce noise and reduce the quality of the signal. To avoid this, use short, thick wires for connections, or consider using a shielded cable to minimize interference. Ideally, the HX711 should be placed close to the load cell to maintain signal integrity.

Poor Connections: Loose or poor connections can result in noisy or unreliable signals. Inspect the connections carefully, ensuring that the pins are soldered properly and the wires are securely attached. A solid connection is essential for reliable data transmission.

Voltage Spikes: Voltage spikes caused by other electronic devices can corrupt the signal. Use capacitors to stabilize the power supply and suppress voltage spikes, or opt for a dedicated power line for the HX711 module.

6. Incorrect Code or Library Usage

Software issues are a common source of problems when using the HX711. Many users may inadvertently make coding errors, leading to incorrect readings or module failure.

Possible Causes and Solutions:

Improper Library Functions: Many developers use libraries like "HX711.h" to interface with the module. Ensure that you are using the latest version of the library and that it is compatible with your hardware. Refer to the official documentation to ensure correct usage of the functions and parameters.

Code Errors: Double-check your code to verify that the HX711 is properly initialized and that the reading functions are called correctly. Pay attention to timing issues as the HX711 requires a certain amount of time to settle between readings.

Sampling Rate Settings: Adjust the sampling rate settings to find a balance between accuracy and speed. A too-fast sampling rate can result in unreliable data, while a too-slow rate might slow down your application. Experiment with different settings to find the best configuration for your setup.

7. Interference from Other Components

If you’re working in a complex system with many other components, the HX711 may experience interference from other sensors or devices. Components like motors, servos, or high-power devices can introduce noise that affects the performance of the HX711.

Possible Causes and Solutions:

Isolation: Try isolating the HX711 from high-powered components by placing it away from motors, servos, or power supplies that might generate interference. Additionally, using separate power supplies for different components can help reduce cross-interference.

Use of Shielding: In some cases, shielding the entire system can help protect the HX711 from external interference. You can use aluminum foil or other conductive materials to create a Faraday cage around the HX711 and its wiring.

8. Final Thoughts on Troubleshooting the HX711

Troubleshooting the HX711 is a systematic process that involves checking both hardware and software aspects. By following these tips and solutions, you can resolve the most common issues that arise with the HX711 module. Whether it’s wiring, power supply issues, or software configuration, identifying the root cause and applying the right solution will ensure that your weight measurement system functions smoothly and accurately.

If you're looking for models of commonly used electronic components or more information about HX711 datasheets, compile all your procurement and CAD information in one place.

( Partnering with an electronic component supplier ) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. ( Contact us ) for free today.