The MICROCHIP MCP2515 CAN Controller is a critical component in modern automotive electronics, providing robust and efficient Communication in vehicles' electronic systems. This article explores various applications of the MCP2515 in the automotive industry, showcasing its importance in improving vehicle functionality, safety, and efficiency. Discover how this versatile component is transforming automotive communication systems and driving innovation in the industry.

MCP2515, CAN controller, automotive electronics, CAN bus, vehicle communication, automotive systems, vehicle safety, car diagnostics, embedded systems, automotive innovations

Introduction to the MCP2515 CAN Controller and Its Role in Automotive Electronics

In recent years, the complexity of automotive systems has grown significantly, with more electronic components being integrated into vehicles to enhance functionality, safety, and user experience. A key enabler of this technological evolution is the Controller Area Network (CAN) bus, which facilitates communication between the various electronic control units (ECUs) within a vehicle. The MCP2515 CAN controller, developed by Microchip Technology, plays a pivotal role in ensuring efficient, reliable, and high-speed communication across these ECUs.

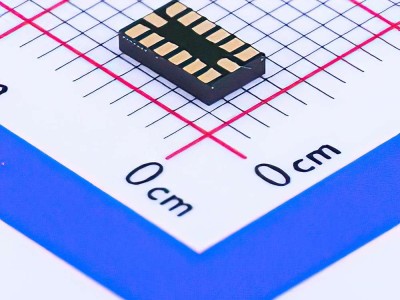

The MCP2515 is a stand-alone, high-speed CAN controller that interface s with a microcontroller via the Serial Peripheral Interface (SPI) bus. This flexibility makes it an ideal solution for integrating CAN communication into embedded systems, particularly in the automotive sector. It is essential for managing complex data exchanges between ECUs that control vital systems like engine Management , braking, and safety features.

In this first part of the article, we will explore the fundamental concepts of CAN communication and how the MCP2515 controller serves as a cornerstone of modern automotive electronics.

What is the MCP2515 CAN Controller?

The MCP2515 is a highly integrated CAN controller that supports both standard (11-bit) and extended (29-bit) identifier formats for CAN communication. This device is designed to operate at speeds up to 1 Mbps, making it suitable for high-speed communication requirements in automotive applications.

At the heart of the MCP2515 is its ability to interface with a microcontroller through SPI, enabling seamless integration into any embedded system. It supports a variety of CAN features, including message filtering, error detection, and automatic retransmission in case of message loss. This level of functionality ensures the robustness and reliability required for critical automotive applications.

Why is CAN Communication Essential in Automotive Systems?

The CAN bus is the backbone of communication in modern vehicles. It allows various ECUs to exchange data efficiently and reliably. In a typical modern vehicle, there are dozens of ECUs, each controlling a specific function, such as the engine control module (ECM), airbag system, transmission control unit, and infotainment system. These ECUs must communicate with each other to ensure proper vehicle operation, safety, and performance.

Without a robust and fast communication protocol like CAN, the coordination between these ECUs would be inefficient, prone to failure, and costly to maintain. The CAN protocol offers several key advantages, including:

Reliability: CAN is known for its error-handling capabilities, ensuring that communication between ECUs is robust even in the presence of noise or interference.

Real-time communication: CAN supports time-critical data transmission, which is crucial for safety-related applications like collision avoidance or emergency braking systems.

Flexibility: CAN allows multiple ECUs to be connected on the same bus, reducing the complexity and wiring costs associated with traditional communication methods.

Cost-effective: CAN controllers, like the MCP2515, are relatively low-cost solutions for adding communication capabilities to embedded systems.

The MCP2515’s Role in Automotive Communication

The MCP2515 CAN controller bridges the gap between a microcontroller and the CAN bus, enabling seamless communication for automotive applications. It provides the necessary functionality for transmitting and receiving CAN messages, which are crucial for various automotive systems. By supporting both standard and extended CAN message formats, the MCP2515 ensures that the controller can handle a wide range of automotive data types.

One of the key features of the MCP2515 is its ability to filter incoming messages based on their identifier, allowing the controller to process only relevant data and improve system efficiency. Additionally, the MCP2515 can store multiple messages in its FIFO buffer, which helps manage the flow of data and ensures that no messages are lost.

In modern vehicles, the MCP2515 is often used in conjunction with microcontrollers or processors to implement complex control functions. For example, it can be used to monitor engine parameters, control braking systems, and manage infotainment systems. The versatility of the MCP2515 allows automotive manufacturers to develop highly integrated and reliable solutions that meet the demanding requirements of today’s vehicles.

Applications of the MCP2515 CAN Controller in Automotive Systems

Now that we have a solid understanding of the MCP2515 and the role of CAN communication in automotive systems, let's take a closer look at some real-world applications where the MCP2515 plays a crucial role.

1. Engine Control and Monitoring

In modern vehicles, engine management systems (EMS) are responsible for controlling the engine’s performance, fuel efficiency, and emissions. The MCP2515 CAN controller is widely used in these systems to enable communication between various engine control units, such as the ECM and the transmission control unit.

The MCP2515 facilitates the exchange of data related to engine parameters, such as RPM, temperature, fuel pressure, and exhaust gas composition. This allows the engine control system to adjust operating conditions in real-time, optimizing performance and reducing emissions. In addition, the ability to monitor these parameters in real-time helps technicians diagnose issues more efficiently, improving vehicle reliability.

2. Advanced Driver Assistance Systems (ADAS)

ADAS technologies, such as adaptive cruise control, lane departure warning, and emergency braking, rely heavily on the exchange of data between sensors and control units. The MCP2515 CAN controller plays a critical role in these systems by providing reliable communication between various ECUs that process sensor data, make decisions, and actuate the necessary responses.

For example, a collision avoidance system uses data from radar, cameras, and ultrasonic sensors to detect obstacles in the vehicle’s path. This data is processed by the ADAS ECU and communicated to the braking system via the CAN bus, enabling the vehicle to apply the brakes automatically if necessary. The MCP2515 ensures that data flows seamlessly and in real-time between these critical systems, contributing to enhanced vehicle safety.

3. Infotainment and Connectivity

Modern vehicles are equipped with sophisticated infotainment systems that provide navigation, media playback, and connectivity features. These systems require constant communication between various ECUs, including the infotainment head unit, Bluetooth module, GPS module, and audio control system.

The MCP2515 CAN controller is often used to enable communication between these ECUs, ensuring that user inputs and data are processed correctly and promptly. Whether it’s adjusting the volume, changing the music source, or navigating to a destination, the MCP2515 ensures that all these functions work together smoothly.

4. Electric and Hybrid Vehicles

Electric and hybrid vehicles have unique requirements compared to traditional internal combustion engine (ICE) vehicles. In these vehicles, the Power train, battery management system (BMS), and energy recovery systems need to communicate efficiently to optimize energy usage and extend the vehicle’s range.

The MCP2515 CAN controller is used in these applications to ensure that data flows between the powertrain control unit (PCU), battery management system (BMS), and other critical systems. This data exchange helps optimize battery charging and discharging cycles, control regenerative braking, and ensure that the vehicle operates at peak efficiency.

Conclusion

The MCP2515 CAN controller is a vital component in modern automotive electronics, enabling the smooth and reliable communication required for a wide range of applications, from engine control to advanced driver assistance systems. Its ability to interface with microcontrollers via SPI and support high-speed, error-free communication makes it an ideal choice for automotive manufacturers looking to enhance vehicle performance, safety, and connectivity.

In the next part of this article, we will continue exploring the specific advantages of using the MCP2515 in automotive applications, as well as its impact on vehicle diagnostics and future automotive innovations.

The Impact of MCP2515 in Automotive Diagnostics and Future Innovations

The Role of MCP2515 in Vehicle Diagnostics

One of the key advantages of using the MCP2515 CAN controller in automotive systems is its role in diagnostics. With modern vehicles becoming increasingly complex, diagnostic tools need to access and analyze data from various ECUs to identify and troubleshoot issues effectively.

The MCP2515 facilitates this by providing a reliable communication link between the vehicle’s ECUs and diagnostic equipment. Through the CAN bus, a diagnostic tool can retrieve real-time data about the vehicle’s performance and identify fault codes that may indicate a malfunction in a particular system. This is particularly valuable for technicians and service centers, as it allows them to perform in-depth diagnostics with minimal effort and time.

For instance, if there is an issue with the engine’s fuel injection system, the diagnostic tool can access the relevant data from the ECM via the MCP2515 controller and provide insights into potential causes. This enables faster repair times, reduces vehicle downtime, and ultimately lowers maintenance costs for vehicle owners.

Integration with Telematics and Fleet Management Systems

Telematics systems are used to monitor and manage fleets of vehicles, providing fleet operators with real-time information about vehicle location, fuel usage, driver behavior, and maintenance needs. The MCP2515 plays a significant role in telematics by enabling the seamless integration of CAN data with telematics units.

By connecting the MCP2515 to a vehicle’s CAN bus, telematics systems can collect and transmit data on key performance indicators (KPIs), including engine health, tire pressure, and battery status. This data can be analyzed to identify trends, optimize routes, and predict maintenance needs, ultimately improving fleet efficiency and reducing operational costs.

The Future of Automotive Communication: Innovations Powered by MCP2515

As the automotive industry continues to evolve, the role of communication systems will become even more critical. With the rise of autonomous vehicles, electric vehicles, and smart cities, there will be an increasing demand for reliable, real-time data exchange between vehicles and infrastructure.

The MCP2515 is well-positioned to support these future innovations. For instance, in autonomous vehicles, real-time communication between sensors, control units, and external infrastructure (such as traffic lights and smart road signs) will be essential for safe and efficient operation. The MCP2515’s high-speed communication capabilities make it an ideal candidate for these applications.

Similarly, in the context of electric vehicles (EVs), the MCP2515 can help manage communication between the battery management system (BMS), the charging infrastructure, and the vehicle’s powertrain, ensuring that energy usage is optimized for maximum range and efficiency.

Conclusion

The MCP2515 CAN controller has proven to be a versatile and indispensable tool in modern automotive electronics. By enabling reliable and efficient communication between various ECUs, the MCP2515 plays a crucial role in enhancing vehicle performance, safety, and functionality. As automotive technology continues to advance, the MCP2515’s contribution to innovations in autonomous driving, electric vehicles, and smart infrastructure will only increase, further cementing its place as a cornerstone of the future of automotive electronics.

This concludes the article on the application examples of the MCP2515 CAN controller in automotive electronics.

Partnering with an electronic components supplier sets your team up for success, ensuring the design, production, and procurement processes are quality and error-free.