Understanding the HGTG30N60A4D IGBT module and the Cause of Short Circuits

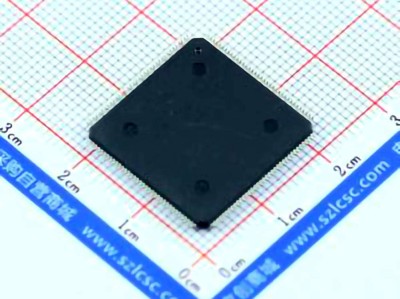

Introduction to the HGTG30N60A4D IGBT Module

The HGTG30N60A4D is a high- Power Insulated Gate Bipolar transistor (IGBT) module designed for efficient switching and amplification in high-voltage and high-current applications. Typically used in motor control, industrial power supplies, and other high-performance systems, this IGBT module offers reliability and high efficiency. However, like any other semiconductor device, the HGTG30N60A4D can experience faults, including short circuits, which can compromise the performance and longevity of the module.

Identifying Short Circuits in IGBT Modules

A short circuit in an IGBT module occurs when unintended contact is made between the collector, emitter, or gate terminals. This can lead to catastrophic failure if not promptly addressed. Short circuits can arise from various issues, including:

Overvoltage or Overcurrent Conditions: High voltages or currents exceeding the IGBT's rated capacity can cause breakdowns in insulation, leading to short circuits.

Incorrect Gate Drive Signals: Improper gate drive signals may fail to switch the transistor on or off correctly, leading to a constant conduction path.

Mechanical Damage: Physical damage to the module, either from external forces or poor handling, can cause internal connections to short.

Environmental Factors: Extreme temperatures, humidity, or contamination can damage the IGBT, leading to internal shorts.

Symptoms of a Short Circuit in an IGBT Module

Recognizing the symptoms of a short circuit in an IGBT module is critical for swift intervention. Common signs of short circuits in the HGTG30N60A4D module include:

Overheating: If the module heats up excessively during operation, it may indicate that there is a short circuit or partial short within the device.

Burnt or Discolored Components: Visual signs of burnt marks, discoloration, or smoke near the module terminals often suggest internal short circuits.

Erratic Performance: The system may experience inconsistent switching, output voltage anomalies, or a complete loss of functionality.

Increased Power Consumption: Short circuits often result in higher power draw due to the increased current flow through the module.

Safety Precautions Before Repair

Before diving into the repair process, ensure that you follow strict safety protocols:

Power Off the System: Always disconnect the system from the power supply before attempting any repair work.

Use Appropriate PPE (Personal Protective Equipment): Insulated gloves, goggles, and protective clothing can safeguard against electrical hazards.

Work in a Static-Free Environment: Electrostatic discharge (ESD) can cause further damage to the IGBT module. Ensure your workspace is free from static build-up.

Quick Repair Techniques for Short Circuits in HGTG30N60A4D IGBT Module

Step 1: Diagnosing the Short Circuit

The first and most crucial step in repairing a short circuit is accurate diagnosis. Here’s how to go about it:

Visual Inspection: Carefully inspect the IGBT module for any signs of visible damage such as burnt spots, cracks, or discoloration. Pay special attention to the gate, collector, and emitter terminals, as well as the body of the module.

Use a Multimeter: Use a digital multimeter (DMM) to test for shorts between the terminals. Set the multimeter to continuity or resistance mode and measure between the collector, emitter, and gate. A reading of 0 ohms or a beep on the continuity setting suggests a short.

Check the Gate Drive Circuit: If the gate drive signals are not functioning properly, this could be the cause of the short. Check for faulty components in the gate drive circuit, such as resistors, capacitor s, or transistors.

Step 2: Replacing Damaged Components

Once you’ve diagnosed the short circuit, it’s time to replace any damaged components. In many cases, the short circuit may have been caused by a failed component within the IGBT module. Here’s how to proceed:

Replacing the IGBT Die: If the short is caused by a damaged IGBT die, you’ll need to replace the entire module. This can be a complex task, requiring precise soldering skills and access to the correct replacement module. For the HGTG30N60A4D, ensure that you source the module from a reputable supplier.

Check for Damage to the Gate Resistor: The gate resistor is critical for ensuring proper switching behavior. If the resistor is damaged due to excessive current or heat, it should be replaced. This is a relatively simple fix and can restore the module’s performance.

Replace the Thermal interface Material: If the module has overheated due to a short circuit, the thermal interface material (TIM) may have degraded. Replace the TIM with high-quality thermal paste or a thermal pad to ensure optimal heat dissipation.

Step 3: Insulating and Rebuilding the Module

After replacing damaged components, ensure that any internal insulation is restored. Insulation failure is one of the leading causes of short circuits in power modules. Here’s how to go about it:

Reapply Insulating Pads: Ensure that insulating pads are placed properly between the IGBT and the heatsink or any other metal components. These pads help prevent accidental shorts and provide mechanical support.

Use High-Quality Thermal Epoxy: If necessary, use thermal epoxy to secure components in place. This epoxy not only acts as an adhesive but also provides insulation and thermal conductivity.

Reassemble the Module: Once all components are replaced and insulation is restored, carefully reassemble the module. Take care to align all pins and connectors properly to avoid further damage.

Step 4: Testing the Repaired Module

After completing the repair, the next crucial step is to test the module to ensure the short circuit has been fully addressed. Follow these steps:

Initial Power-On Test: Power up the system slowly, monitoring the module closely for any signs of overheating or abnormal behavior.

Measure Key Parameters: Use an oscilloscope or multimeter to measure key parameters such as gate voltage, collector-emitter voltage, and current. These measurements will ensure that the module is functioning within its specified limits.

Perform Load Testing: If possible, perform load testing to ensure that the IGBT module is capable of handling the required current and voltage under real-world operating conditions.

Monitor for Long-Term Stability: Over the course of several hours or days, continue to monitor the module for any signs of instability or reoccurrence of the short circuit.

Step 5: Preventing Future Short Circuits

To minimize the likelihood of short circuits in the future, implement the following preventive measures:

Use Proper Gate Drive Circuitry: Ensure that the gate drive circuit is designed correctly and is protected against overvoltage, overcurrent, and other faults.

Implement Surge Protection: Surge protection devices can help protect the IGBT module from voltage spikes that could lead to a short circuit.

Improve Cooling and Ventilation: Ensure that the module is adequately cooled to prevent overheating, which can damage internal components and lead to shorts.

Regular Maintenance and Inspection: Periodically inspect the IGBT module for signs of wear and tear. Early detection of potential issues can help prevent costly repairs.

Conclusion

Short circuits in the HGTG30N60A4D IGBT module can significantly affect the performance of your power electronics system. However, by following the right repair techniques and safety precautions, you can quickly diagnose and resolve these issues. Always remember to replace damaged components, restore insulation, and test the module thoroughly to ensure that it returns to optimal performance. By incorporating preventive measures, you can extend the lifespan of the module and maintain the reliability of your system.

With these quick and efficient repair techniques at your disposal, you can tackle short circuit issues in IGBT modules with confidence and precision.

If you are looking for more information on commonly used Electronic Components Models or about Electronic Components Product Catalog datasheets, compile all purchasing and CAD information into one place.