The TM TM1640 is a popular LED driver chip commonly used in various electronic displays and systems. While it's a reliable component, users may sometimes face issues. In this article, we dive into the most common problems encountered with the TM1640 and their practical solutions. Whether you're a beginner or an experienced engineer, this guide will provide you with effective troubleshooting techniques to ensure your system operates smoothly.

TM1640, troubleshooting, solutions, LED driver, electronics, common issues, display, system errors, LED matrix, digital display, circuit troubleshooting.

Understanding the TM1640 and Common Problems

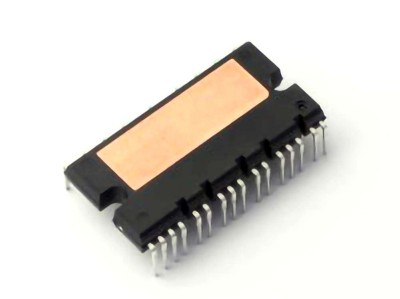

The TM1640 is an integrated circuit (IC) designed to control 16-segment LED displays, commonly used in devices like clocks, digital counters, and electronic signage. Known for its efficiency and low power consumption, the TM1640 enables easy control of a large number of LEDs with minimal wiring. However, despite its advantages, there are situations where users encounter issues while working with this versatile chip. In this first part, we’ll explore the common problems you might face and their potential causes.

1. Incorrect Display Output or No Output at All

One of the most common issues users face when working with the TM1640 is an incorrect or completely blank display. This issue could stem from several causes, and understanding each possibility will help you troubleshoot efficiently.

Possible Causes:

Incorrect Wiring or Connection: Ensure that the wiring to the TM1640 is correctly configured. The TM1640 typically connects to a microcontroller (MCU) via a serial interface. Any loose connections, short circuits, or misconnected pins can lead to the display malfunctioning.

Faulty Power Supply: The TM1640 requires a stable 5V power supply. A fluctuating or insufficient voltage can cause the display to either flicker, show incorrect data, or not work at all. Always measure the voltage supply to confirm it meets the required level.

Incorrect Timing or Data Protocol: The TM1640 operates based on a specific timing protocol, particularly when communicating with an MCU. If the timing of the data transmission is incorrect, the display will not show the expected output. Be sure to follow the recommended timing diagrams and protocols in the datasheet.

Software or Firmware Issues: A programming error can lead to the TM1640 not displaying the correct data. Check the microcontroller code for bugs, especially around the initialization process, data transmission, and timing.

Solutions:

Verify all pin connections and ensure the wiring is correct according to the TM1640 datasheet.

Measure the power supply voltage with a multimeter to confirm it is stable at 5V.

Double-check your code, especially the data transmission protocols. Make sure the MCU is sending the data in the correct format and at the correct timing intervals.

2. Flickering or Inconsistent Brightness

Flickering or inconsistent brightness in the LED display can be another frustrating issue. It often occurs when the TM1640 does not receive stable input signals or when there are hardware issues. This issue could also be a result of improper voltage regulation or low-quality power sources.

Possible Causes:

Power Supply Instability: As mentioned earlier, the TM1640 requires a stable voltage supply. Any fluctuation in voltage or inadequate power delivery can result in the LEDs flickering. Check if the power supply is providing consistent voltage within the required range.

Grounding Issues: Improper grounding can lead to unstable signals and cause the display to flicker. Ensure that the ground pin of the TM1640 is securely connected to the common ground of the power supply and the MCU.

Excessive Current Draw: If the LED matrix connected to the TM1640 is drawing more current than it is rated for, the chip may fail to operate correctly, causing flickering or dim displays.

Signal Interference: Electromagnetic interference (EMI) or noise from nearby components may interfere with the data signals being sent to the TM1640, leading to flickering.

Solutions:

Ensure the power supply is regulated and provides a consistent 5V output. Consider using a capacitor across the power supply input to reduce voltage fluctuations.

Improve the grounding of the circuit by ensuring that all components share a common ground, and avoid long ground traces to minimize voltage drops.

Check the current draw of the LEDs connected to the TM1640 to ensure it is within the recommended limits.

Use shielded cables or add Capacitors to the signal lines to reduce EMI or noise interference.

3. Data Corruption or Distorted Display

If the display shows incorrect characters or distorted data, it could be due to data corruption during transmission. The TM1640 uses a serial communication protocol (such as I2C or SPI) to receive data from the microcontroller. Any disruption in this communication process can lead to corrupted data being displayed.

Possible Causes:

Incorrect Data Format: The TM1640 expects data in a specific format, and sending the wrong data type can result in display corruption. Ensure that the data being sent to the TM1640 is correctly formatted according to the chip's requirements.

Signal Timing Issues: The TM1640 uses precise timing for data transmission. If the microcontroller is not adhering to the correct timing intervals, the data may be misinterpreted, leading to garbled output. Review the timing diagrams in the datasheet to ensure proper synchronization.

Faulty Connections: Loose connections or poor soldering on the communication lines (data, clock, etc.) can cause incomplete or corrupted data transmission.

Solutions:

Double-check the data format being sent to the TM1640. Refer to the datasheet for the exact format and communication protocol.

Review the timing diagrams to ensure that the microcontroller is sending data at the correct intervals. Adjust the software code if necessary to match the timing specifications.

Inspect the communication lines for loose or poor solder joints. Rework any problematic connections to ensure a reliable data transfer.

Advanced Troubleshooting and Preventative Solutions

While the common issues discussed in Part 1 cover most troubleshooting scenarios, there are also advanced techniques and preventative measures that can help ensure your TM1640-based display system functions flawlessly over time. This section dives deeper into complex problems and offers additional strategies for maintaining optimal performance.

4. Overheating or Chip Failure

Overheating can be a significant concern when using the TM1640, especially when driving large LED matrices. Prolonged heat buildup can damage the chip, leading to permanent failure or erratic behavior. Overheating is often a result of excessive current draw or improper heat dissipation.

Possible Causes:

Excessive Load: If the LED matrix is too large or the current draw is too high, the TM1640 may overheat. Each segment on the matrix requires current, and if the total current exceeds the rated limits, the chip can overheat.

Insufficient Cooling: In some designs, especially those driving large or high-power LEDs, adequate cooling might not be provided. Lack of proper heat sinking or airflow can cause the chip to overheat.

Improper Voltage Regulation: If the supply voltage is higher than recommended (e.g., above 5.5V), the TM1640 may overheat and fail. Overvoltage can lead to internal damage, even if the chip appears to be functioning initially.

Solutions:

Ensure that the power supply provides the correct voltage (5V) and can handle the current requirements of the LEDs. Consider adding a current-limiting resistor to protect the TM1640.

If you're driving a large LED matrix, consider using heat sinks or adding passive cooling (such as a small fan) to help dissipate heat.

If you're using high-power LEDs, consider using a separate power driver circuit to take the load off the TM1640, or use an alternative IC designed for higher currents.

5. Compatibility Issues with Other Components

When integrating the TM1640 into a larger system, compatibility issues may arise with other components, particularly when it comes to voltage levels, communication protocols, or power requirements. These compatibility issues can cause erratic behavior or even prevent the system from working altogether.

Possible Causes:

Voltage Level Incompatibility: If the TM1640 is interfacing with components that use different logic levels (e.g., 3.3V logic from the MCU while the TM1640 requires 5V), communication can fail, and the display might not operate correctly.

I2C/SPI Bus Conflicts: The TM1640 may share its I2C or SPI bus with other devices. Conflicts or incorrect addressing can lead to data collision or miscommunication.

Power Supply Conflicts: If the TM1640 and other components are drawing power from different sources with unbalanced voltages, instability may occur.

Solutions:

Use level shifters or ensure that all components operate at compatible voltage levels.

Make sure that the I2C or SPI bus is properly managed and that devices on the bus have unique addresses to avoid conflicts.

Ensure that the power supply for the entire system is stable and can supply sufficient current to all components.

6. Preventative Maintenance and Long-Term Solutions

To ensure the long-term reliability of your TM1640-based system, consider implementing some preventative measures during the initial design and setup phases. By addressing potential problems before they arise, you can minimize downtime and extend the life of your display.

Preventative Measures:

Use Capacitors: Adding bypass capacitors (e.g., 0.1µF and 10µF) near the power supply pins of the TM1640 can help filter out noise and provide stable voltage.

Circuit Protection : Implement over-voltage protection (e.g., zener diodes) and current-limiting resistors to protect the chip from unexpected voltage spikes or excessive current.

Proper PCB Layout: If you are designing a custom PCB, pay careful attention to the layout. Keep the signal traces as short as possible, and use separate ground planes for analog and digital signals to minimize noise.

Conclusion

The TM1640 is a reliable and efficient component for driving LED displays, but like any electronic device, it can encounter issues. By understanding the common problems and solutions, as well as implementing preventative measures, you can ensure your TM1640-powered systems run smoothly. Troubleshooting requires patience and attention to detail, but with the right knowledge, you'll be able to tackle any issue that arises, keeping your display systems functioning at their best.

If you're looking for models of commonly used electronic components or more information about TM1640 datasheets, compile all your procurement and CAD information in one place.

( Partnering with an electronic component supplier ) sets your team up for success, ensuring that the design, production and procurement processes are streamlined and error-free. ( Contact us ) for free today.